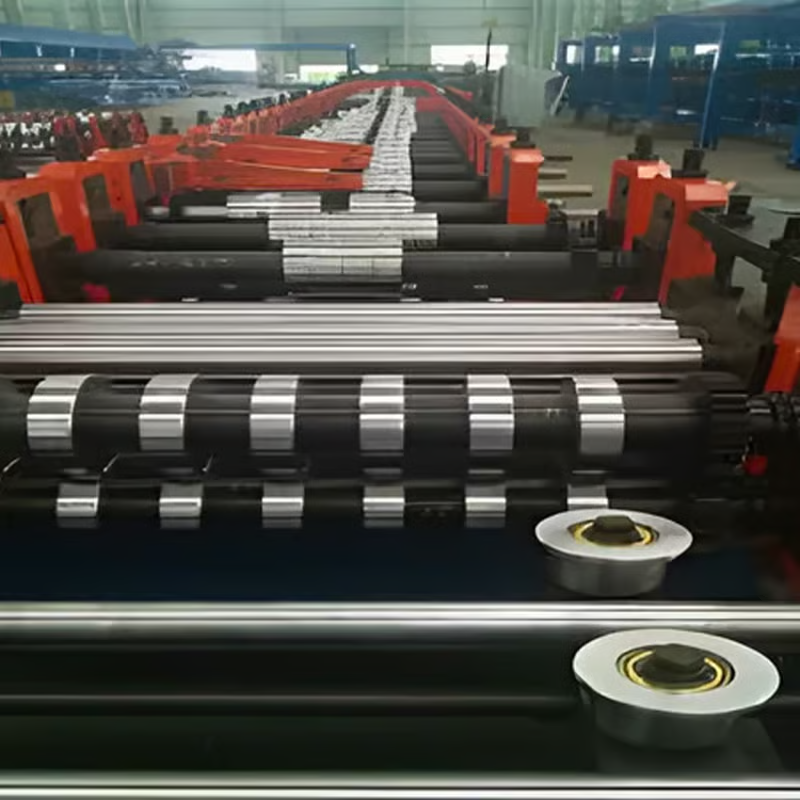

A double layer packing box roll forming machine is a versatile and efficient type of equipment used in industrial settings to produce packaging boxes. This machine is capable of creating double-layered boxes with precision and speed, making it a valuable asset for businesses looking to optimize their production processes.

Features of Double Layer Packing Box Roll Forming Machine

One of the key features of a double layer packing box roll forming machine is its ability to produce different sizes and shapes of boxes. This machine also offers flexibility in terms of material compatibility, allowing businesses to work with a variety of packaging materials. Additionally, these machines are easy to operate and maintain, making them a cost-effective solution for packaging needs.

Benefits of Using Double Layer Packing Box Roll Forming Machine

There are several benefits to using a double layer packing box roll forming machine, including increased efficiency, precision, and speed in the production process. These machines can help businesses save time and resources by automating the box-making process and reducing the risk of errors.

Applications of Double Layer Packing Box Roll Forming Machine

Double layer packing box roll forming machines are commonly used in industries such as food and beverage, pharmaceuticals, electronics, and e-commerce. These machines can be customized to meet specific production requirements, making them suitable for a wide range of packaging needs.

Factors to Consider When Choosing a Double Layer Packing Box Roll Forming Machine

When selecting a double layer packing box roll forming machine, it is important to consider factors such as production capacity, speed, material compatibility, and overall cost. Businesses should also assess the machine's durability, reliability, and ease of maintenance to ensure long-term success.

Latest Technological Advancements in Double Layer Packing Box Roll Forming Machine

Recent advancements in technology have enhanced the performance and capabilities of double layer packing box roll forming machines. New features such as automated controls, real-time monitoring, and adaptive tooling systems have improved efficiency and accuracy in box production.

Future Trends in Double Layer Packing Box Roll Forming Machine Industry

The double layer packing box roll forming machine industry is expected to witness continued growth and innovation in the coming years. Manufacturers are focusing on developing eco-friendly and energy-efficient machines to meet the demands of sustainable packaging solutions.

Comparing Double Layer Packing Box Roll Forming Machine with Traditional Methods

Compared to traditional box-making methods, double layer packing box roll forming machines offer higher production rates, better quality control, and reduced labor costs. These machines also have a smaller footprint, making them suitable for businesses with limited space.

Case Studies: Success Stories of Using Double Layer Packing Box Roll Forming Machine

Many businesses have reported significant improvements in their packaging operations after investing in double layer packing box roll forming machines. Case studies have shown increased productivity, cost savings, and customer satisfaction as a result of using these advanced machines.

Conclusion

In conclusion, a double layer packing box roll forming machine is a valuable asset for businesses seeking to streamline their packaging processes and improve efficiency. With advanced features, customization options, and cost-effective benefits, these machines are a worthwhile investment for industries that rely on high-quality packaging solutions.

Quote Inquiry

Contact us!